Introduction

Innovation is the lifeblood of modern industry, and Lepbound is here to prove it. Whether you’re manufacturing the next generation of electric vehicles or designing cutting-edge medical devices, solid and reliable adhesives are no longer an option—they’re a necessity. Lepbound is more than just a bonding agent; it’s a game-changer.

What sets Lepbound apart is its ability to form ultra-strong, environmentally resistant bonds across diverse materials while meeting the growing demand for sustainable solutions. By diving deeper into Lepbound’s unique properties and real-world applications, we can uncover why this technology is earning its place as the future of adhesive innovation.

Table of Contents

What is Lepbound?

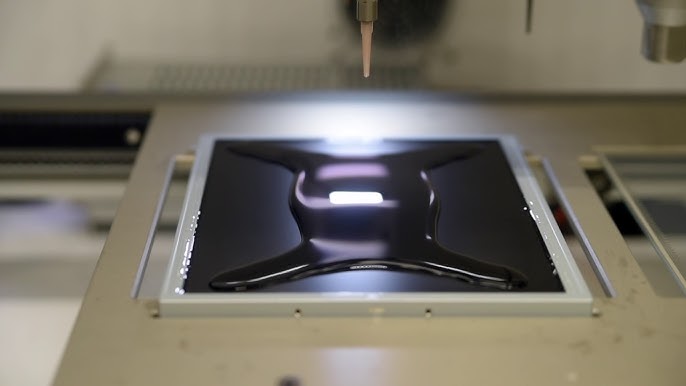

At its core, Lepbound is a next-generation bonding solution designed to outperform traditional adhesives in strength, versatility, and longevity. Developed using advanced molecular bonding techniques, Lepbound creates ultra-durable, reliable connections under even the harshest conditions.

Let’s break it down:

- Strength: Lepbound bonds can withstand incredible stress and weight, making them ideal for industrial use.

- Flexibility: Whether bonding metals, plastics, or composites, Lepbound adapts seamlessly to a variety of materials.

- Longevity: Unlike traditional adhesives, Lepbound doesn’t degrade quickly, saving costs in the long run.

Why Lepbound Stands Out

You might wonder, “Why should I switch to Lepbound?” It’s a fair question, especially when traditional adhesives have served industries for decades. But as industries evolve, so do their challenges—and traditional adhesives simply can’t keep up.

Superior Bond Strength

Imagine building a high-speed electric train or a spacecraft. The materials must endure extreme stress without compromising safety. Lepbound’s molecular bonding ensures that these structures hold firm, even in the most demanding environments.

Resilience to Harsh Conditions

Lepbound doesn’t shy away from challenges:

- High Temperatures: Whether it’s the scorching heat of a car engine or freezing aerospace conditions, Lepbound delivers unmatched performance.

- Chemical Resistance: Consider medical devices exposed to sterilization or machinery in corrosive environments—Lepbound doesn’t falter.

- Sustainability at Its Core

In a world increasingly prioritizing sustainability, Lepbound is leading the charge. By extending the life of products and reducing waste, Lepbound helps manufacturers align with eco-conscious goals without sacrificing performance.

Real-World Applications of Lepbound

Automotive Innovation

The automotive industry is all about efficiency and durability. Take electric vehicle manufacturers, for instance. Lepbound enables lightweight designs by bonding advanced composites, reducing vehicle weight, and improving energy efficiency. From securing battery modules to assembling car frames, Lepbound ensures reliability, which is where it matters most.

Revolutionizing Aerospace

The aerospace industry demands perfection—there’s no room for error. Aircraft components bonded with Lepbound withstand extreme pressure and temperature and contribute to lighter, fuel-efficient designs. NASA, for example, has recently been exploring next-gen adhesives like Lepbound to enhance the durability of spacecraft under intense conditions.

Precision in Medical Devices

Consider a surgical tool that must remain sterile yet durable through multiple procedures. Lepbound ensures strong bonds between biocompatible materials, making it a go-to adhesive for implants, prosthetics, and surgical equipment.

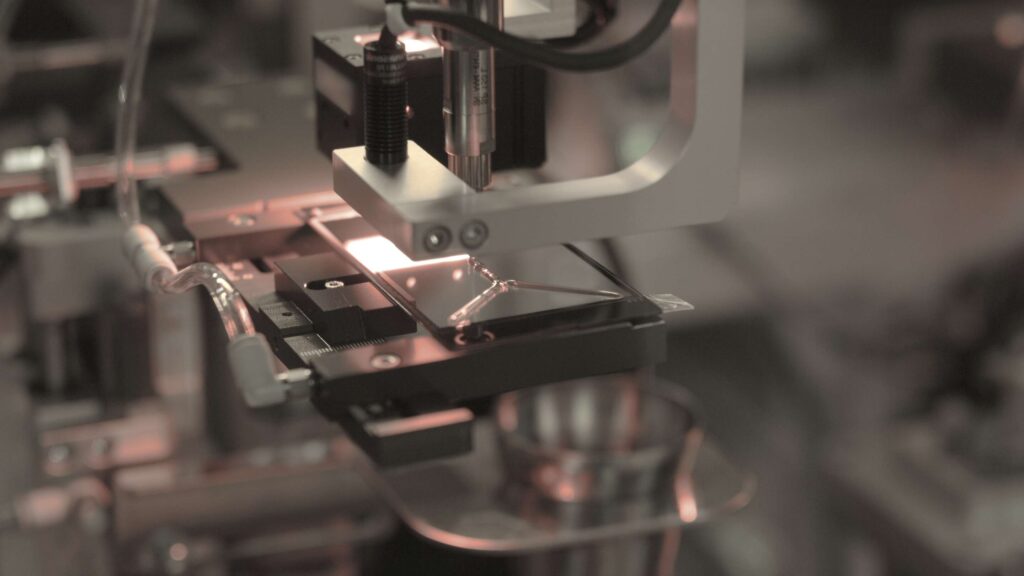

Building Smarter Electronics

In electronics, where miniaturization is critical, Lepbound provides precision bonding for components like microchips and wearable devices. Think about your smartphone or smartwatch—Lepbound-level technology keeps everything in place while ensuring durability.

Infrastructure That Lasts

From towering skyscrapers to expansive bridges, infrastructure projects depend on adhesives that withstand decades of wear and tear. Lepbound’s weather resistance and durability ensure that these structures stand the test of time.

Key Benefits of Adopting Lepbound

Improved Product Quality

Manufacturers using Lepbound report fewer product defects, reduced recalls, and enhanced customer satisfaction. In competitive industries, this reliability builds trust and brand loyalty.

Cost-Effective in the Long Run

While Lepbound might require a slightly higher initial investment, its durability reduces maintenance and replacement costs, making it an economically sound choice.

Safer, Smarter Solutions

Safety is non-negotiable for industries like aerospace and healthcare. Lepbound’s ability to maintain bond integrity under extreme conditions reduces risks and ensures compliance with strict safety standards.

Sustainability That Matters

With reduced waste, longer-lasting products, and alignment with eco-friendly practices, Lepbound supports businesses looking to meet environmental regulations and consumer expectations.

How to Implement Lepbound in Your Processes

Adopting Lepbound technology might seem like a big step, but the process is more straightforward than you think.

- Evaluate Material Compatibility: Test Lepbound with your materials to ensure they meet your specific needs.

- Invest in Training: Equip your staff with the knowledge they need to apply Lepbound correctly. Proper application ensures you get the best results.

- Monitor and Optimize: Review Lepbound’s performance in your production lines regularly. Minor tweaks can lead to even greater efficiency.

What’s Next for Lepbound?

The future of Lepbound is full of promise. Research teams are already exploring the integration of nanotechnology to make bonds even more robust and lighter. Additionally, the development of recyclable adhesives is in progress, aiming to reduce the environmental impact of adhesive production and disposal.

As these innovations roll out, Lepbound will continue to set new standards in bonding technology, driving industries forward.

FAQs

How does Lepbound differ from traditional adhesives?

Lepbound offers superior strength, versatility, and resistance to harsh conditions, unlike conventional adhesives.

Can Lepbound be used for high-temperature applications?

Absolutely! Lepbound thrives in extreme environments, making it ideal for industries like aerospace and automotive.

Is Lepbound eco-friendly?

Yes, Lepbound supports sustainability by reducing waste and extending product lifecycles.

Does Lepbound require special equipment?

Specialized equipment may sometimes be needed, but proper training ensures seamless integration into your processes.

Conclusion

Lepbound isn’t just a product; it’s a technological revolution. With its unmatched strength, environmental resistance, and commitment to sustainability, Lepbound is setting a new standard for adhesives across industries.

Whether you’re designing the next big thing in aerospace or manufacturing consumer goods that last, Lepbound has the power to transform your operations. Don’t wait—embrace the future of bonding technology today.

Recommended Articles

Washer Review Miracoup: The Ultimate Guide to Choosing the Perfect Washer

Revolutionizing Esports: A Deep Dive into ProjectRethink.org Team Esports

Everything You Need to Know About TraceLoans.com: A Complete Guide to Smarter Loan Decisions